Australian scientists from CSIRO have achieved a breakthrough in clean energy by setting a new efficiency record for fully printed solar cells.

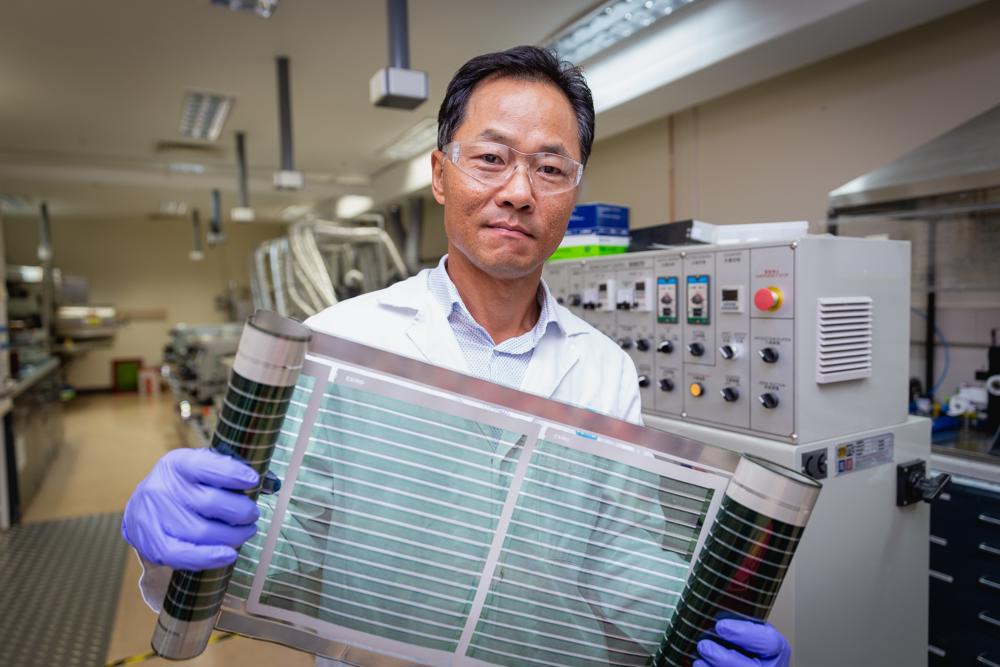

This technology, printed on thin plastic films, is lightweight and flexible, expanding the possibilities for solar energy use.

Unlike rigid silicon panels, these printed cells are highly flexible and portable, making them suitable for various applications, including urban construction, mining, emergencies, and even space exploration.

This achievement is the result of over a decade of research and development, solving engineering challenges to achieve record results.

CSIRO Principal Research Scientist Dr Doojin Vak said: “We developed a system for rapidly producing and testing over 10,000 solar cells a day — something that would have been impossible to do manually.

“This allowed us to identify the optimal settings for the various parameters in the roll-to-roll process and quickly pinpoint the conditions that deliver the best results.”

The use of roll-to-roll printing allows for the mass production of solar cells on long rolls of plastic, making production more accessible and cost-effective.

The successful commercialisation of this technology could bring significant economic and environmental benefits.

The printed solar cells incorporate an advanced material called perovskite, which can be formulated into inks for industrial printers.

This eliminates the need for expensive metals like gold, further reducing production costs.

While perovskite solar cells currently trail silicon in efficiency and lifetime, their lightweight and flexibility offer unique advantages for applications requiring mobility and versatility.

CSIRO is actively seeking industry partners to further develop and commercialise this technology, which received funding from ARENA’s Research and Development Program (Solar PV Research).

The team has demonstrated impressive performance, achieving 15.5 per cent efficiency on a small scale and 11 per cent for a 50 square centimetre module, a record for fully printed solar cells.

Automatic screening was used to optimise the printing process, and carbon-based inks replaced gold, reducing costs while maintaining high performance.

Technoeconomic modelling has been used to predict production costs in Australia.