Researchers in Japan have developed a groundbreaking plastic that dissolves in seawater within hours, presenting a promising solution to the escalating problem of ocean pollution and its devastating impact on marine life.

The innovation, spearheaded by scientists at the RIKEN Center for Emergent Matter Science and the University of Tokyo, marks a significant leap forward in the quest for sustainable alternatives to conventional plastics.

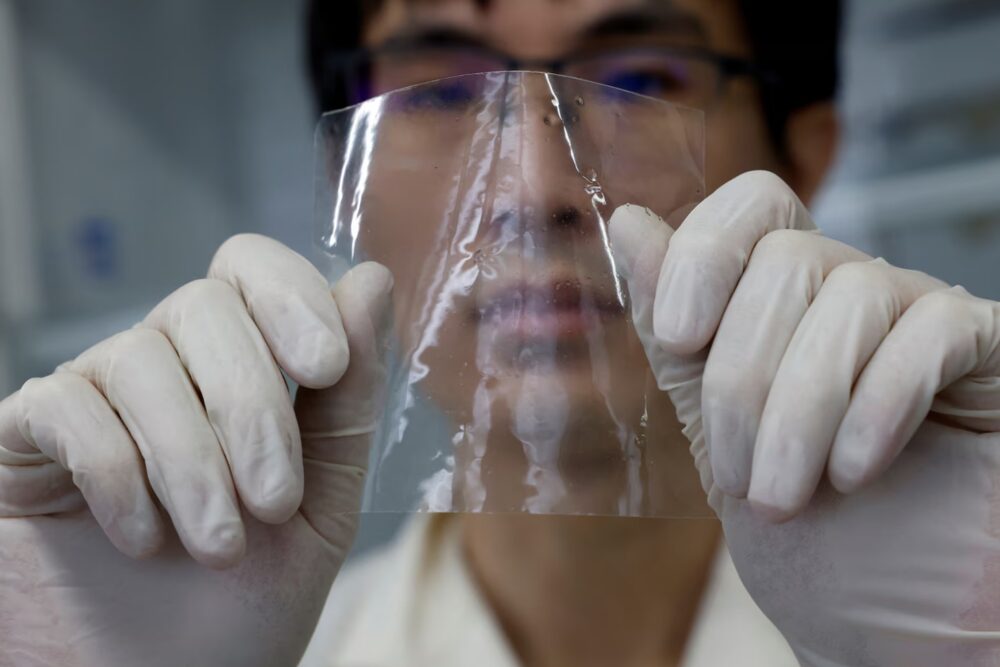

At a laboratory demonstration in Wako city near Tokyo, the research team showcased a small piece of their new plastic vanishing in a container of salt water after being stirred for about an hour.

Unlike previous biodegradable plastics, which often persist in marine environments, this material breaks down rapidly and leaves no residual trace.

Project lead Takuzo Aida explained: “Children cannot choose the planet they will live on. It is our duty as scientists to ensure that we leave them with best possible environment.”

He noted the new plastic is as strong as petroleum-based alternatives but, when exposed to salt, decomposes into its original components.

These components can then be further processed by naturally occurring bacteria, thereby avoiding the generation of microplastics that threaten aquatic life and enter the food chain.

The urgency of such innovations is underscored by predictions from the United Nations Environment Programme, which estimates that plastic pollution is set to triple by 2040, adding 23–37 million metric tonnes of waste to the world’s oceans each year.

Scientists globally are racing to find effective solutions, with efforts highlighted by campaigns such as World Environment Day on June 5.

While the Japanese team has not yet detailed plans for commercialisation, Aida noted: “Their research has attracted significant interest, including from those in the packaging sector.”

The plastic is also non-toxic, non-flammable, and does not emit carbon dioxide, making it a strong candidate for eco-friendly packaging and other applications.

Aida added that salt is also present in soil, allowing a five-centimetre piece of the material to disintegrate on land after just over 200 hours.

The team is now focusing on optimising coating methods so the plastic can be used like regular plastic without sacrificing performance.

![SMART ENERGY WEEK 2025 [February]](https://greenreview.com.au/wp-content/uploads/2024/11/Green-Review_1000x667.jpg)