Together with Vestre, the Norwegian manufacturer of urban furniture, BIG-Bjarke Ingels Group unveils The Plus as the world’s most sustainable furniture factory tucked in the heart of the Norwegian forest.

Envisioned as a village for a community dedicated to the cleanest, carbon neutral fabrication of urban and social furniture, The Plus aims to be a global destination for sustainable architecture and high-efficiency production. As Norway’s single largest investment in furniture in decades, the 6,500m2 open production facility will double as a public 300-acre park for hiking and camping while serving as a landmark aligned with the region’s mission to establish a green manufacturing industry. The Plus is set to begin construction this year.

“Vestre will be the world’s most sustainable furniture manufacturer. Building The Plus will be an important step in reaching this goal. By using cutting-edge technology and Scandinavian collaboration, we can produce faster and greener than ever. In that way we will ensure global competitiveness through our leadership in environmentally-conscious production,” said Jan Christian Vestre, CEO of Vestre.

Image by Lucian R.

The Plus will be the first industrial building in the Nordic region to achieve BREAM Outstanding, the highest environmental certification. All materials are carefully chosen by their environmental impact, with the façade constructed from local timber, low-carbon concrete and recycled reinforcement steel. Designed to be a ‘Paris Agreement-proof’ building, every aspect of the design is based on principles of renewable and clean energy to match Vestre’s eco-friendly production, such as ensuring a minimum of 50 per cent lower greenhouse gas emissions than comparable factories.

The Plus is located in the village of Magnor, in the geographical midpoint between Vestre’s headquarter in Oslo and the company’s existing steel factory in Torsby, Sweden. The building is conceived as a radial array of four main production halls – the warehouse, the colour factory, the wood factory and the assembly – that connect at the centre. The layout enables an efficient, flexible and transparent workflow between the manufacturing units, thus generating the ‘plus’ shape at its intersection.

Image by Lucian R.

“With Vestre we have imagined a factory that is simultaneously front of house and back of house. The beauty of the factory is the clarity of its organisation. Conceived as the intersection of a road and a production line it forms a large plus connecting everything to everything. The radical transparency invites visitors and hikers to enjoy the whole process of manufacturing while providing the workers the thrill of working in the middle of the forest,” said Bjarke Ingels, Founder & Creative Director, BIG.

At the centre of The Plus is the logistics office and exhibition center with direct connections to all four production halls, allowing Vestre’s employees to process logistical traffic with maximum efficiency. The central hub wraps around a public, circular courtyard where the latest outdoor furniture collections are prominently exhibited with the changing seasons. The outdoor plaza doubles as a panopticon for visitors and staff to experience the factory’s production processes in full transparency.

Image by Lucian R.

“Playfulness, democracy and sustainability is at the heart of the Vestre brand and everything they do, so it makes absolute sense to create a wooden and colorful factory in the middle of the Norwegian woods, surrounded by a 300,000m2 public forest park. The local community can come to experience the unique gigantic Vestre furniture pieces sprinkled in as sculptures in the park. Working with Jan Christian Vestre and his team has been the pleasure of a lifetime. An ambitious and dedicated client who not only sets the bar high when it comes to sustainability but is a true visionary who wants to change the world, while treating everyone fairly along the way,” said David Zahle, Partner, BIG.

The Plus will employ several Industry 4.0 solutions, such as smart robots, self-driving trucks, and a tablet to manage the entire factory. Every machine is assigned one of Vestre’s 200 colours, which spill onto the floors and lead back into the central roundabout. This colourful mapping of the machinery lends strong visual cues that help guide and explain the workflow of the Vestre production facility, allowing visitors to easily follow the production process as if touring a museum.

Image by Lucian R.

“The entire interior is organised like a flowchart – with the colour of each machine overflowing to include the floors. As you explore The Plus, you move through a functional archipelago of colourful islands – overview and experience become one and the same,” said Mr Ingels.

Image by Lucian R.

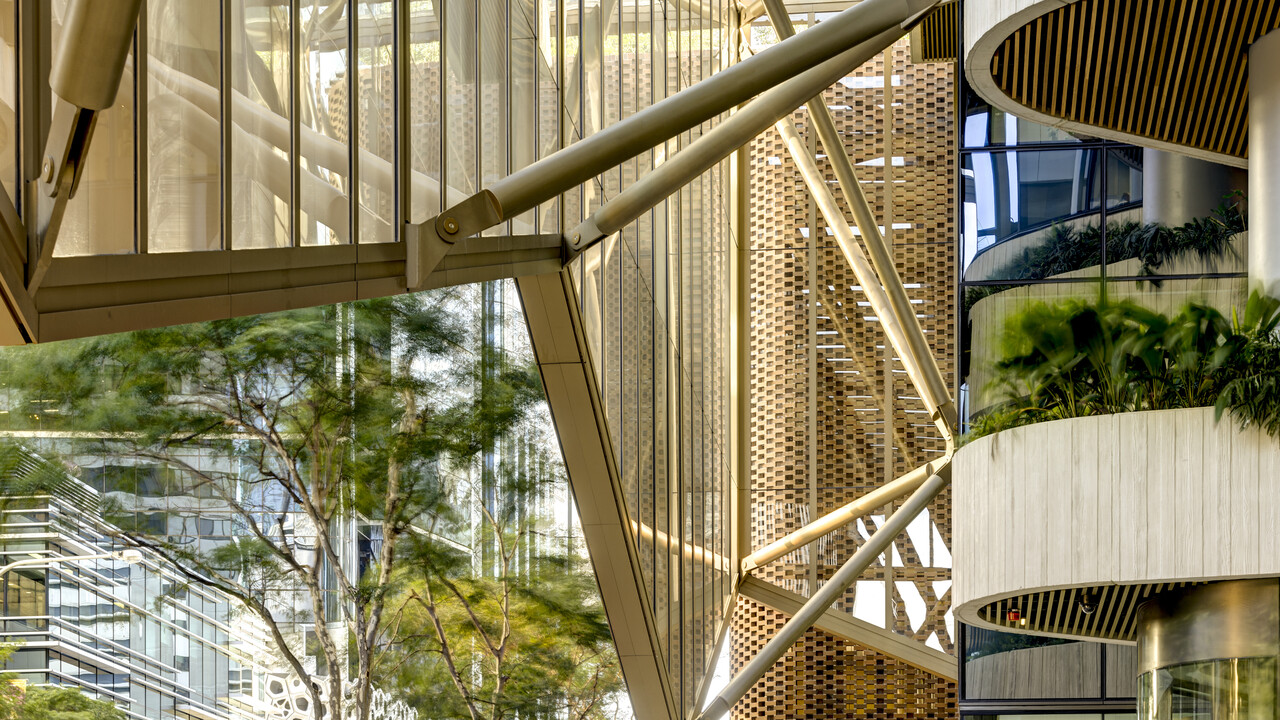

Each factory wing has one alternating ceiling corner lifted to create inclined roofs that allow views inside to the production halls and outside to the forest canopies. Along the colour and wood factory, the sloping roofs are extended to form a pathway for visitors and staff to hike up and down the building while following the production processes inside. The four production units will be built with a 21m free-spanning, cross-laminated timber, creating flexible column free-spaces. A 3m wide service corridor provides the technical infrastructure and the structural stability for each wing.

Image by Lucian R.

From all four sides of the buildings, visitors and staff are invited to hike around the facility and conclude on the green roof terrace, transforming the furniture factory museum into a campus in the woods. An ADA-accessible ramp allows wheelchairs and strollers to meander the serpentine path and enjoy the immersive experience of being among the pine trees. The Plus reinforces Vestre’s vision of combining social and democratic spaces with a future enriched by technology yet grounded in history and nature.

On the rooftop, 1,200 photovoltaic panels are placed and angled according to optimal solar efficiency. Excess heat from the panels are connected to an ice-water system for cooling, heat and cold storage tanks, heat pumps and energy wells as a storage support system. Overall, the system contributes to at least 90 per cent lower energy demand than that of a similar conventional factory.

The Plus has the potential to lead as an example for how advancements in fabrication and manufacturing will shape factories of the future. The Plus is BIG’s second project in Norway, following the opening of The Twist at Kistefos Sculpture Park in Jevnaker last year.