Compressors and the compressed air they generate are used in a multitude of applications. However, the fact that compressor exhaust heat can be harnessed often remains forgotten.

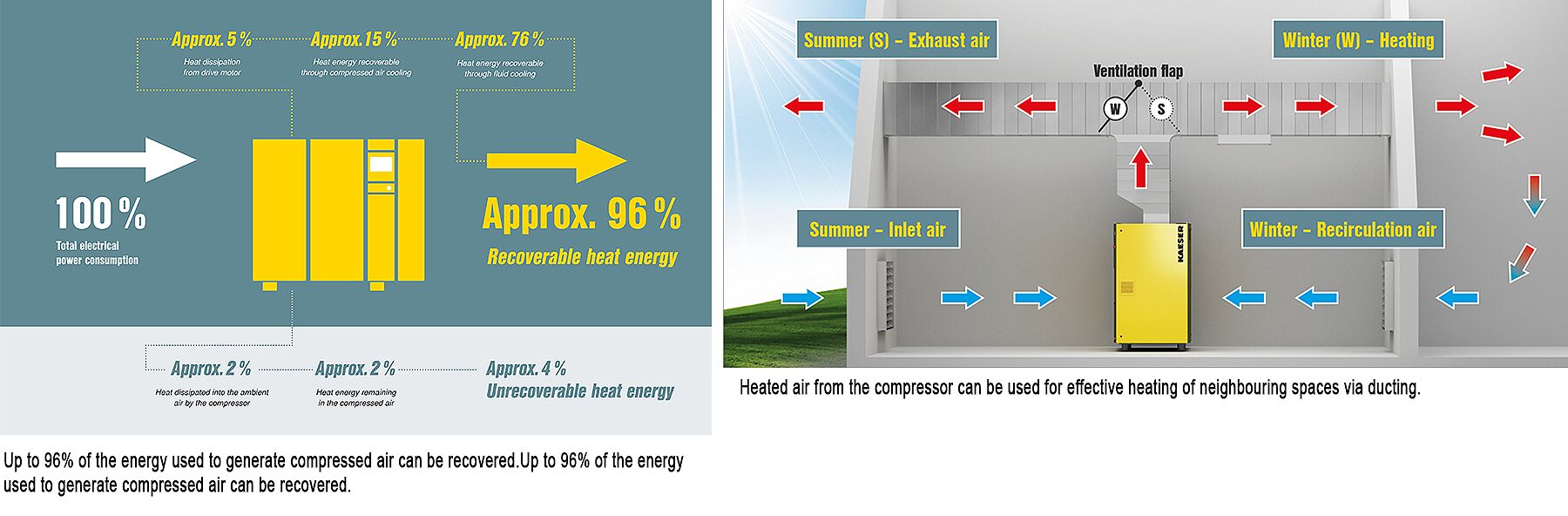

Up to 96% of the drive energy supplied to a compressor is available for reuse and this is referred to as “heat recovery”. Heat recovery not only saves energy and costs, but also reduces the operator’s CO² footprint.

Of course, this heat could simply be conveyed away. However, there are plenty of ways to make use of this readily available energy source that occurs as a by-product of the compression process. The simplest and most efficient method is to use the compressor exhaust heat directly, e.g. for heating adjoining rooms or spaces.

Here, instead of discharging hot air from the compressed air station outside, an air ducting system directs it to neighbouring warehouses or workshops. When no hot air is required, the heated exhaust air is simply conveyed outdoors by means of a flap or louvre. A thermostatically controlled louvre enables hot air to be provided as and when required in order to maintain a constant temperature.

In addition to providing full or supplementary heating for operating spaces, hot compressor exhaust air can be used to support applications such as drying processes, generating hot air curtains or preheating burner air for heating systems. The corresponding investment costs can often be amortised within a period of one year.

Compressor exhaust heat can also be used to supply existing hot water heating and service water systems; depending on the available storage capacity, water temperatures of over 70ºC can be generated.

There are several ways to achieve this. The most cost-effective method is to use a plate-type heat exchanger integrated into the compressor, which is connected to the compressor cooling fluid circuit and transfers energy from the heated cooling fluid to the water that requires heating. Depending on whether the hot water is required for particularly sensitive production or cleaning processes, for showering and washing, or for general heating systems, special safety heat exchangers or conventional plate-type heat exchangers may be used.

These enable 70 – 80% of the installed compressor output to be used for heating purposes without the need for any additional expenditure on energy. This variant of heat recovery is also possible with primary water-cooled rotary screw compressors. Heat recovery is principally worthwhile when the compressors in question feature a power output of at least 5.5 kW.

Establishing actual requirement

Since very few operators know their exact air demand, it is worth conducting a compressed air audit before installing a compressor system. Performed using state-of-the-art analysis tools such as the ADA/KESS (Air Demand Analysis/Kaeser Energy Saving System), this audit can determine the precise demand data for a project. This data can then be used to determine the planning steps for the air station operator, as well as the investment costs and potential for energy savings.

In the case of a completely new installation, optimised solutions are devised and suggested from the outset so that the operator can compare independently between different system variants and select the most cost-efficient choice.

Where building management systems are used, it is recommended to conduct a thermal audit in conjunction with the compressed air audit so that the heat balance can be determined in parallel with the air consumption. This allows thermal data such as temperature flow and return to be investigated in addition to compressed air data such as volume, pressure and required air quality.

Once these details are established, it can be determined what percentage of the compressor exhaust heat can be absorbed into the normal heat requirement of the project. This in turn allows the size of the storage vessel and the required temperature to be calculated. In the best-case scenario, 96% of the heat output can be used.

What to consider:

A few points must be taken into account when planning or optimising a compressed air station. For example, compressors and heating systems should not be placed in the same room, since optimal use of these requires different room climate conditions and the compressor must not be permitted to draw in dangerous admixtures.

The compressor room needs to be well ventilated; the room for the heating system does not. In an ideal world, the two rooms would be separate but situated near to one another, so that the ducting route between compressors and heating system can be as short as possible.

Since the volume of accumulating heat and the heat requirement are rarely identical, it is important to ensure that there is sufficient thermal storage potential in the form of large vessels. This guarantees optimum supply when generation and consumption volumes differ.

Air- or water-cooled compressors?

Once the design has been decided, it is vital to select the correct compressors. In general, two different cooling methods are available for compressors: air cooling and water cooling.

In the case of the former, air ducts with thermostatically controlled flaps convey the hot exhaust air directly from the compressors to the neighbouring operating spaces. To minimise heat losses, the distance the exhaust air needs to travel from the compressor to the point of use should not be too far.

Even if it is not required year-round, heat recovery with this type of system pays dividends: the required investment for heat recovery is relatively low and can usually be amortised within just a year. Systems equipped with additional hot water heat recovery can supply water at temperatures up to 70ºC throughout the year, and even higher if needed.

In the case of water-cooled compressors, the user-end requirements and cooling water costs also play an important role; in principle, however, heat recovery as described above can also be achieved here by means of a second connected circuit.

In summary, heat recovery can significantly increase the efficiency of a compressed air system and reduce environmental damage by preventing emissions of greenhouse gas.