As the European Union prepares to become a world-leader in sustainable battery technology and manufacturing, the Consortium for Battery Innovation (CBI) has launched a new European research project using neutron diffraction in a bid to improve the lifetime of energy storage batteries.

The high-tech process, which images the entire crystal structure of the battery as it operates, allows battery experts to observe and control the processes impacting battery life and performance.

The project is being conducted in collaboration with the Instituto de Nanociencia y Materiales de Aragón (INMA) and battery company Exide Technologies. It is one of a range of advanced battery innovation studies underway and funded by the CBI.

As countries target rapid carbon reduction in the battle to halt climate change, battery energy storage is set to become one of the defining technologies of the century, with demand predicted to grow to 20,000-megawatt hours (MWh) by 2025.

Advanced lead batteries are a critical part of this landscape, with Europe home to leading manufacturing, recycling and research capability.

Scientists will be joining forces from INMA, a joint institute between one of Spain’s oldest universities, the University of Zaragoza, and the largest public research institution in Spain and third-largest in Europe, the Spanish National Research Council (CSIC) and Exide Technologies, through one of its research and development centres based near Madrid.

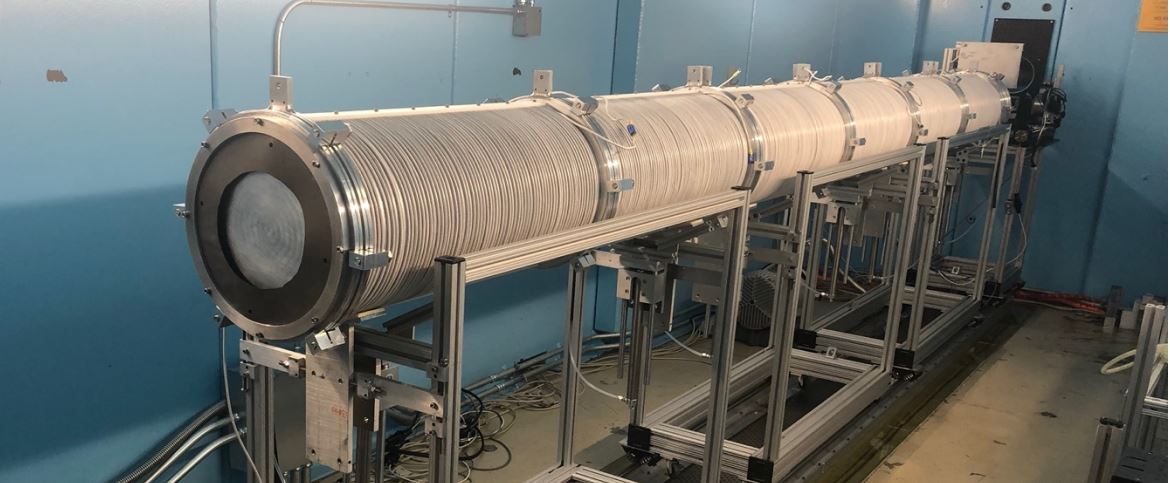

They will study the fundamental processes that govern recharge efficiency and battery electrode failure using a suite of neutron beamline experiments.

Through a specific focus on battery electrodes, which transfer energy to and from the electrolyte in order to power the polarised device to which they connect, neutron diffraction will be used to study the batteries in operation across different duty cycles.

For energy storage applications, many of which incorporate renewable energy elements, advanced lead batteries operate at partial-state-of-charge (PSoC) and in high depth-of-discharge (DoD), both demanding duty cycles.

Director of CBI, Dr Alistair Davidson, said the ability to probe battery electrodes in real-time under typical energy storage duty cycles will deliver vital insights into how to enhance performance and the overall lifetime of the battery.

“This information is a critical part of our advanced battery research program which aims to ensure advanced lead batteries continue to innovate to meet heightened demand for clean, renewable energy storage across the globe,” Dr Davidson said.

Neutron diffraction is capable of not only mapping the activity of the surface of the electrodes, but the entire electrode and electrolyte present in the battery. This provides a complete picture of how battery electrodes are changing at the micro-level, something never before done in lead battery research.

By describing the electrode phenomena that govern battery lifetime, the research is generating new information on how to control the active material and maximise battery life in all applications for advanced lead batteries, a key goal in CBI’s technical roadmap.

Demand for clean energy storage continues to soar across Europe and further afield, and pioneering research will be significant in ensuring advanced lead batteries continue to innovate to meet the future technical requirements of these systems.

About the Consortium for Battery Innovation (CBI)

CBI is the world’s only global pre-competitive research organisation funding research into lead batteries for energy storage, motive and automotive applications.

For more than 25 years, with its global membership of battery manufacturers, industry suppliers, research institutes and universities, CBI has delivered cutting-edge research pushing the boundaries of innovation in lead battery technology, setting the standard for advanced lead batteries and the next generation of energy storage.

For more information, visit: www.batteryinnovation.org

About Exide Technologies

Exide Technologies, headquartered near Paris, France, is a leading provider of advanced energy storage solutions for the automotive and industrial markets.

It designs, manufactures and markets today’s and next-generation battery technologies used across a wide range of applications, from automotive and off-road to material handling, stationary, rail and defence.

Exide Technologies serves the global markets with top-notch battery technologies, know-how and added-value services under many well-known brands.

As an original equipment manufacturer to leading automotive and industrial equipment manufacturers, Exide Technologies has been involved in many of the significant breakthrough energy-storage developments that are enabling innovation across the markets.

With two research and development facilities, nine production plants and three recycling plants in Europe, Exide is committed to high-quality engineering, manufacturing and recycling, and continues to power the world with the most efficient energy solutions and helping customers maximise productivity and performance.

About Instituto de Nanociencia y Materiales de Aragón (INMA)

The Aragon Nanoscience and Materials Institute is a Joint Research Centre created in 2020 by the Universidad de Zaragoza and the Spanish National Research Council (CSIC) as a result of the merging of the Instituto de Ciencia de Materiales de Aragón (founded in 1985) and the Instituto de Nanociencia de Aragón (founded in 2003).

Hosting around 300 members, INMA covers four key research topics (materials for energy and environment, materials for biomedicine, materials for ICT, and new nanoscale phenomena) and two enabling research areas (synthesis, processing and scaling-up of functional materials, and advanced experimental technologies).

INMA has wide experience in participating and managing national and international research projects (more than 30 ongoing EU projects) and works closely with industry through private contracts.

INMA researchers and Exide have been working in collaboration since 2015 to improve the efficiency of the charge-discharge cycles in order to extend the cycle life of the batteries.