Solid-state batteries are emerging as the next frontier in battery technology, and Japan is at the forefront of this innovation. With the potential to revolutionise electric vehicles and energy storage, Japanese companies are making significant strides in commercialising this technology.

Toyota, one of Japan’s leading automakers, has teamed up with Idemitsu Kosan, a major oil company, to develop mass-production technology for solid-state batteries.

Their collaboration aims to bring these batteries to the market by 2027-2028 — promising enhanced safety and energy density over traditional lithium-ion batteries.

AGC, a prominent Japanese glass manufacturer, has also made waves with its prototype all-solid-state battery cell, boasting improved safety and energy density compared to lithium-ion.

Similarly, Idemitsu Kosan has achieved a breakthrough by developing a new sulphide-based solid electrolyte material with high ionic conductivity and stability.

These advancements highlight Japan’s commitment to solid-state battery technology, with research and development efforts dating back decades.

The country’s automotive and materials industries are positioning themselves as leaders in this space, recognising the technology’s potential to drive the mass adoption of electric vehicles.

Market forecasts further highlight the significance of solid-state batteries, with the global market expected to reach ¥3.8 trillion ($38.2 billion) by 2030.

This growth is driven by increasing demand from the electric vehicle and energy storage sectors, as solid-state batteries offer greater range, safety, and faster charging capabilities.

Japan’s dedication to solid-state battery development is evident in recent announcements and partnerships, such as Nissan‘s unveiling of a prototype production facility for all-solid-state batteries.

With plans to launch an electric vehicle equipped with in-house developed solid-state batteries by fiscal 2028, Nissan is poised to make a significant impact in the electric vehicle market.

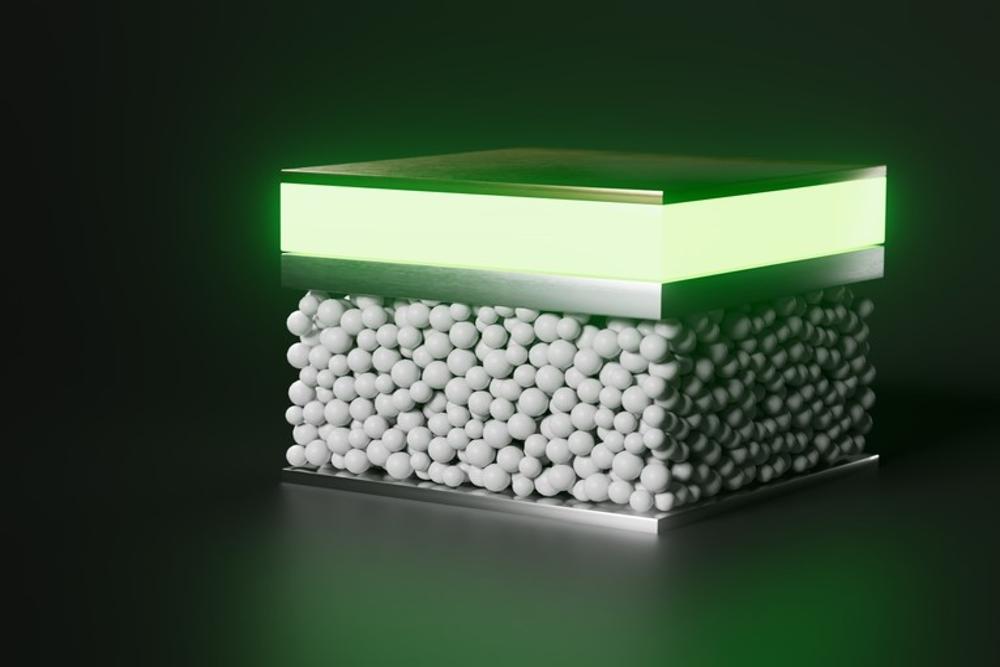

Solid-state batteries use solid electrolytes (ceramics, polymers, or glass) instead of liquids, offering higher energy density and safety.

They can use metallic lithium anodes and oxide/sulphide cathodes for even more efficiency.

These batteries charge faster, last longer, and are said to be safer due to their non-flammable electrolytes.

Despite the progress, challenges remain, including ensuring good contact between the solid electrolyte and electrodes, improving durability, and reducing manufacturing costs.

However, with ongoing research and development efforts, Japan is well-positioned to lead the charge in commercialising solid-state batteries, driving the future of electric vehicles and energy storage forward.