Each year, sales of alkaline batteries in Australia total around 6,000 tonnes. In 2019, the nation’s Battery Stewardship Council estimated that, at the end of their useful life, 97 per cent of those batteries were disposed of in municipal waste streams and reported to landfill.

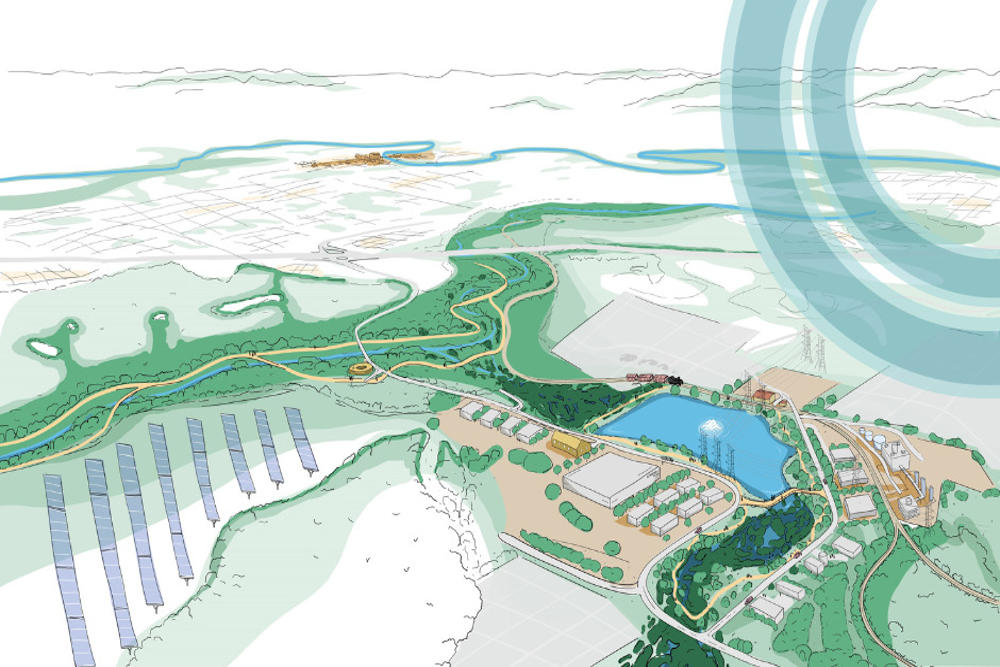

Lithium Australia NL aspires to ‘close the loop’ on the energy-metal cycle in an ethical and sustainable manner.

As part of its commitment to a circular battery economy (and thus its environmental and social governance responsibilities), the company recently assessed the use of zinc and manganese recovered from recycled alkaline batteries as micro-nutrient supplements in fertilisers.

Alkaline mixed metal dust (MMD)

Alkaline MMD is produced by Lithium Australia’s wholly-owned subsidiary Envirostream Australia Pty Ltd at its spent-battery recycling facility in Victoria, Australia.

Envirostream collects the spent alkaline batteries from pick-up points at numerous locations.

After sorting, the alkaline batteries are mechanically shredded, with the cathode and anode active compounds (collectively referred to as MMD) separated.

That material contains high levels of zinc and manganese and minor amounts of graphite and potassium; the zinc and manganese are of the most interest as fertiliser micro-nutrients.

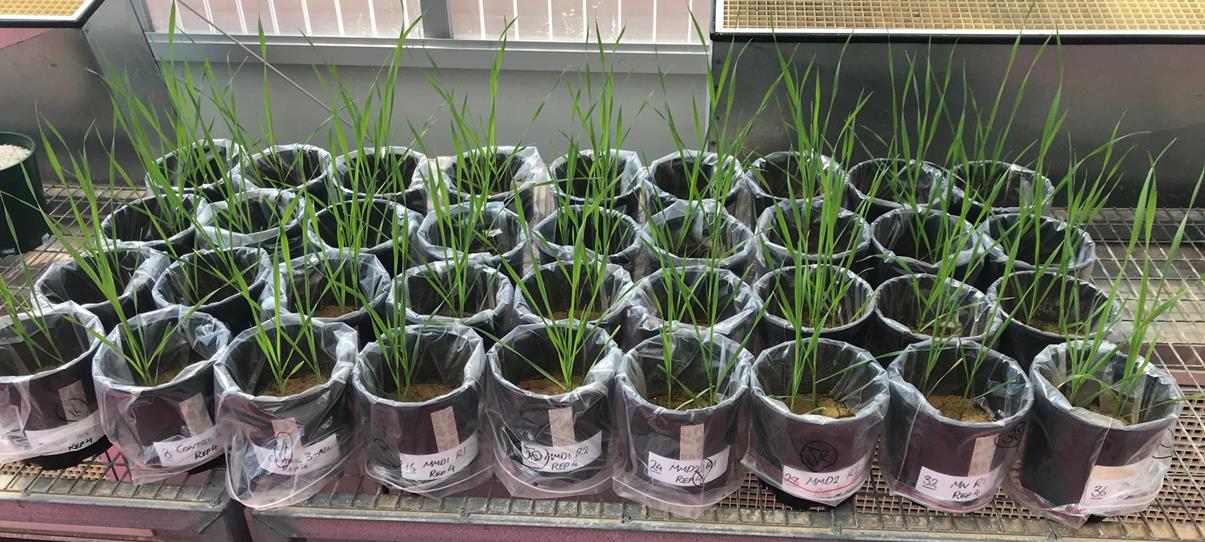

Glasshouse pot trials

Glasshouse pot trials were completed under the direction of the Lithium Australia’s consulting agronomist. Nine tests were conducted on a quadruplicate basis to statistically assess MMD performance as a fertiliser against control samples.

Control tests included: no micro-nutrients, zinc as fertiliser grade ZnSO4, manganese as fertiliser grade MnSO4, and a combination of zinc and manganese as sulphates.

Lithium Australia detailed that the trials concluded:

- Plant dry matter yields were comparable across all samples (controls and MMD).

- Uptake of zinc and manganese from the MMD was observed, however, as expected, it was slower in comparison to that of fertiliser-grade sulphate products over the compressed duration of the glasshouse pot trial.

The results were ‘encouraging enough’ for the company to commit to the next stage of assessment, which may include:

- Blended fertiliser agglomeration testing with an ammonium phosphate-based fertiliser such as monoammonium phosphate (MAP) or diammonium phosphate (DAP).

- Use of these blended samples in larger-scale field trials to assess the yield performance of the MMD in comparison to commercial fertiliser products.

Lithium Australia MD, Adrian Griffin, says that the sustainable and ethical supply of critical materials is a global challenge.

“Recycling all the metals within spent batteries is something that’s rarely done effectively, which is why it remains a target for the company,” he detailed.

“We have not limited ourselves to recycling only lithium-ion batteries but, rather, have included alkaline batteries in a bid to eliminate all such items from landfill.”

“We’re cognisant of the environmental implications of burying such ‘waste’ and encourage all consumers to join us in recycling every spent battery for the benefit of the environment now for the sake of the future,” Mr Griffin concluded.