Two of Schneider Electric’s factories have been designated as new Lighthouses by the World Economic Forum.

The Monterrey 1 facility in Mexico has been named an Advanced Lighthouse, while the Shanghai factory in China has been recognised as an End-to-End Lighthouse.

These designations bring Schneider Electric’s total number of Lighthouse factories to seven, joining previously recognised facilities in Wuxi, China; Batam, Indonesia; Le Vaudreuil, France; Lexington, Kentucky; and Hyderabad, India.

The Global Lighthouse Network, co-founded by the World Economic Forum and McKinsey & Company in 2018, now comprises 172 factories showcasing innovative use of Fourth Industrial Revolution technologies.

The Shanghai facility, which produces critical electrical system devices, faced a surge in global orders and a fourfold increase in SKUs over four years.

To meet this growing demand, the factory:

- Increased automation by 20 per cent

- Implemented advanced technologies such as machine learning-enabled prototyping

- Utilised smart planning and scheduling

- Employed GenAI-driven maintenance

These improvements resulted in a 67 per cent reduction in make-to-order lead time and an 82 per cent increase in labour productivity.

The Monterrey 1 factory in Mexico deployed digital technologies to enhance supply chain resilience and agility.

Key improvements include:

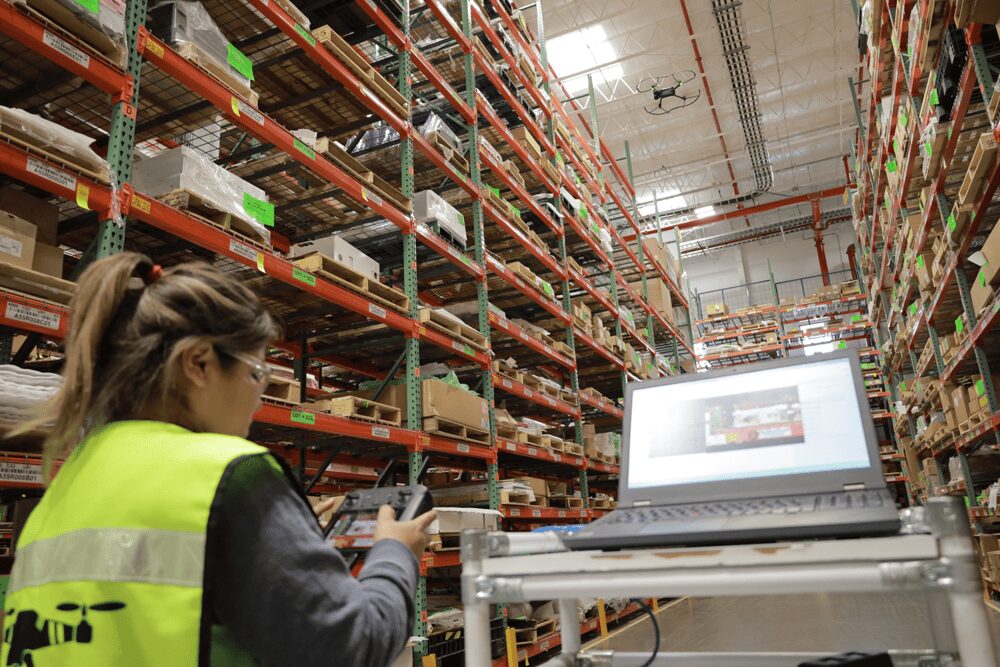

- Implementation of autonomous robots and drone technology for efficient material handling

- Adoption of building and energy management systems, reducing energy and water consumption by approximately 30 per cent

- Utilisation of machine learning for demand forecasting and deep learning for quality inspections

These advancements led to an annual growth rate of 24 per cent while reducing manufacturing costs by 16 per cent, product defects by 20 per cent, and customer lead time by 49 per cent over three years.

Mourad Tamoud, Schneider Electric’s Chief Supply Chain Officer, emphasised the importance of investing in digital technologies and the workforce to strengthen operational capabilities and mitigate risks.

Kiva Allgood, Head of the World Economic Forum’s Centre for Advanced Manufacturing and Supply Chains, noted that these Lighthouse factories are “breaking through the AI hype” and setting new standards for digital transformation in manufacturing.

Schneider Electric’s Impact Supply Chain program, which underpins these achievements, focuses on empowering people, building a sustainable supply chain, delivering quality to customers, and driving performance through advanced technology and collaborative design.