The University of NSW SMaRT Centre has published three scientific papers that show waste coffee grounds and hydrogen from other wastes can be used as part of its patented Green Steel technology.

In the latest research breakthroughs on the centre’s Green Steel Polymer Injection Technology, industrial trials with partner Molycop have shown various wastes can be used to more sustainably make steel in electric arc furnaces.

Wastes including plastic and coffee grounds now join waste rubber tyres as alternative sources of coke and coal as carbon sources for steel making.

They can also provide the element hydrogen, which vastly improves the efficiency and energy required for the manufacturing process.

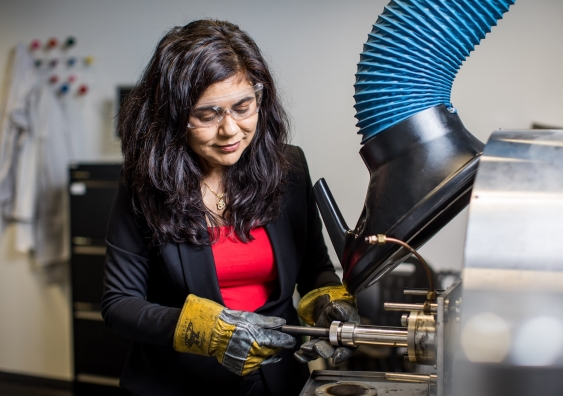

UNSW SMaRT Centre director Professor Veena Sahajwalla noted steelmakers had to meet the demands of quality requirements.

She said: “It gives you the kind of productivity requirements that any commercial operator will want.

“We’ve proven that it does the job at a comparable level, so we’re going to be at least sitting at an equivalent performance – if I’m going to be so bold and brave, I’d love to show that it can do even better.

Professor Sahajwalla pointed out Australian steelmakers were leaders in the space globally.

She continued: “We’re the first to be able to take all of these technological advances and show that it can be done.

“The ideal would be if we completely eliminate the coke.

“If you have a combination of materials, you get a better outcome because you’re able to finetune and customise green steel and take the kinds of materials that do the best job.”

“This is not a waste, it’s a really useful resource – it’s going to be an interesting shift towards valuing our waste resources and thinking about those innovative supply chains where recycling and manufacturing can be coupled together.”