After a big day on site there is nothing more dreaded than the slurry clean-up, often ending with dried cement on the lawn and garden, or plumes of fried cement on roads and footpaths. When this gets washed into the groundwater and drains it often blocks drains and causes flooding. This usually results in the site manager or builder incurring significant financial penalties. Enter Slurrytub, an innovative and sustainable disposal solution for water-saturated site waste, and this scenario becomes a thing of the past.

Essentially a portable filtering system, Slurrytub prevents slurry getting washed down drains or left to ruin lawns and gardens when tradies and DIYers take clean-up shortcuts. Both practical and cost-effective, it helps protect the environment and stormwater infrastructure.

Simple, practical solution to work site cleanup

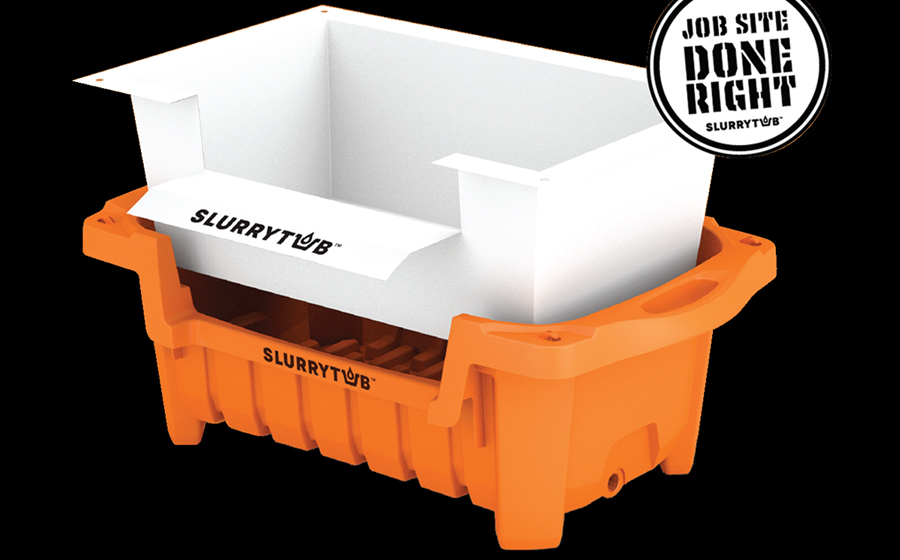

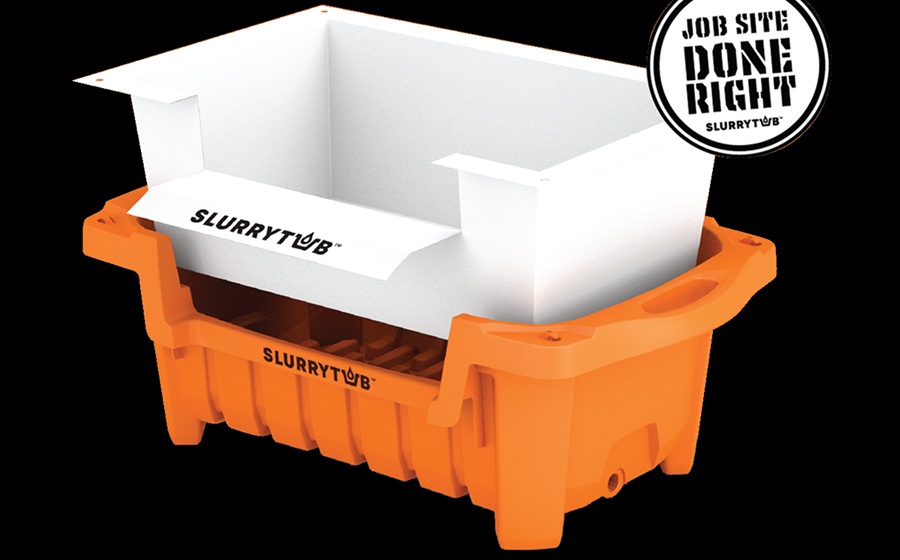

Slurrytub is the brainchild of a respected Sydney builder who dealt with the problem of wash-up waste on his own building sites for many years. He observed that the construction industry guidelines for disposing of slurry were impractical and often ignored, so he decided to do something about it. His game-changing patented design is fundamentally a heavy-duty tub made out of recyclable polypropylene, the cut out at the front of the tub supports most wheelbarrows, hands free. A single use biodegradable filter lines the tub and traps the concrete slurry, leaving sediment-free water to drain into designated wash-up zones. When the slurry waste dries, it can simply be dumped with the filter into a skip.

“It’s as simple as the three Ds: drain, dry and dispose,” explains Slurrytub CEO David Flintoff. “And it can all be done in less than 30 minutes.”

Highly practical, the tub has incorporated two handles for easy movement around site, when filled or empty, and it can also be chained up so it doesn’t get stolen from a site if it’s drying overnight. Already proving a hit, Slurrytub has been successfully trialled by the Council of the City of Sydney, which awarded an Innovation Grant for Environmental Performance 2019/2020 to conduct trials on sites around the city. More than 30 individual building sites have since tested its performance and Slurrytub has been given the thumbs up, with a 100 per cent rating from the contractors who tested it.

Additionally, Henley Homes, one of Australia’s largest and acclaimed home builders has adopted the Slurrytub for all its building sites, reinforcing its place as an industry leader with regards to environmentally responsible practices. Significantly, Slurrytub has been certified by Good Environmental Choice Australia (GECA), an eco-label that provides an independent ‘tick’ to show that the product is great for the environment, lowers the impact on human health and has been ethically made. GECA’s goal is to empower architects, builders, designers and consumers to have confidence in their purchasing decisions. Their rigorous standards follow ISO 14024 principles and ISEAL frameworks for global best practice in eco-labelling, which are then independently assessed by their Assurance Providers.

Slurry in, clean water out.

“GECA’s certification is a weighty endorsement for Slurrytub’s sustainability credentials, proving that this clean, simple system contributes to the environmental performance of building sites and overall stormwater quality,” says Flintoff.

The May 2021 global launch of Australian made and owned Slurrytub saw the release of a starter kit, retailing online at $129 for a tub and six-pack of filters. Replacement filters will be available online in packs of 6.

For more information about SLURRYTUB visit the website here